Hydraulic pumps are one of the most important pieces in a hydraulic system, and they’re used extensively for construction. Hydraulic pumps are used in many industries, and they are an integral part of our everyday lives.

They’re a critical component to power equipment like construction cranes, excavators, dump trucks, and tractors.

However, the most common use for hydraulic pumps is a braking system on nearly every car ever made. This blog post will give you information on where and how hydraulic pumps are being used today!

What is a Hydraulic Pump and What Does it Do?

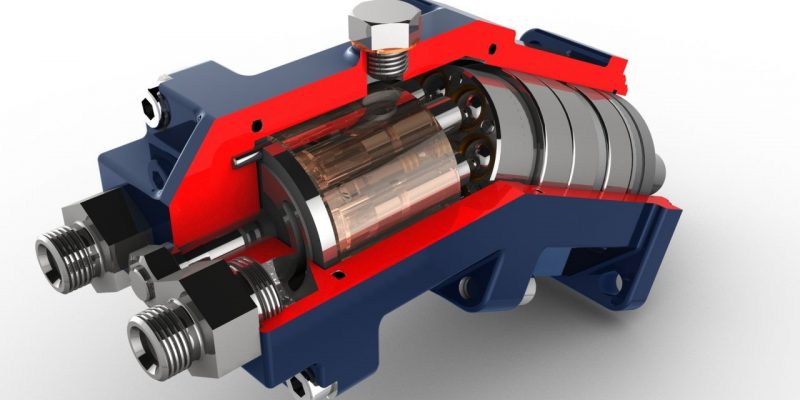

A hydraulic pump is a mechanical device that moves fluid using a piston. The first written reference to a hydraulic pump was in 1845, and it mentioned how one could use it to “raise water from lower levels or suction filtrate.”

The most common use for a hydraulic pump is to create pressure in the system. The fluid moves through the piston, which creates an increase in pressure within the cylinder that it’s located in. This, of course, means that there will also be less volume available within the same space with increased pressure – because when you compress something, its volume decreases.

That means that the fluid will then have to flow back out of the cylinder, and this is where it becomes important for a hydraulic pump about other mechanical components – like pumps or motors.

A hydraulic pump is one of many components in a system that provides power, which can be used to do work like lifting heavy objects and controlling their motion. Like other types of engines, it uses energy from fuel sources such as gasoline or diesel fuel with an air intake and produces kinetic energy in the form of rotational force to create pressure.

Hydraulic pumps are also responsible for creating force in certain devices or equipment – like construction cranes where they provide upward motion on jibs or boom sections of crane systems. A single piston in a hydraulic pump can create up to 13,000 pounds of force.

Where are Hydraulic Pumps Used?

They can be found on construction sites, farms, mines, quarries, vehicles like cars or motorcycles – even elevators use them.

Just some of the common places hydraulic pumps are used today:

- Construction cranes to provide upward motion on jibs or boom sections and for crane systems in general.

- On vehicles such as cars, motorcycles, boats, tractors – pretty much anything with a braking system uses a hydraulic pump for that purpose.

- In manufacturing plants, they’re used to provide pressure for process fluids – like in a paper mill.

- In mines and quarries, hydraulic pumps are used to power equipment that needs high amounts of force or torque, such as the bucket on an excavator.

- Hydraulic pumps can also be found in some elevators where they use them to control movement.

- Hydraulic pumps are also used in flour mills, and they can be found on grain dryers as well.

- Gravity water systems can also use hydraulic pumps to push fluids uphill, which is why they are often found on farms and in mining operations where it’s necessary for inputs or outputs of a system.

- They are used in log splitter systems, but you have to find out what size hydraulic pump for a log splitter.

- They are also used in the production of asphalt and some other road-building materials.

- Hydraulic pumps are also used in industrial processes like oil drilling where they provide energy for the operation.

- And finally, hydraulic pumps are being put to use for power steering systems or anti-lock brake systems (ABS) – which is a system that prevents the wheels from locking up when braking by reducing the pressure on the brakes.

Types of Hydraulic Pumps and Their Uses

There are mainly 6 different types of Hydraulic Pumps:

- Gear Pumps: Gear pumps are the oldest type of hydraulic pump. They had been used for centuries in various applications, such as powering looms and water wheels. Gear Pumps are most often found pumping fluids at low-pressure levels with a high flow rate.

- Piston Pumps: Piston pumps are among the most popular hydraulic pump types today. They use a piston to create head pressure applied against an inlet port to transfer fluid from one side of the pump to another, pumping it into a discharge pipe at high pressures.

- Vane Pumps: Vane pumps are powered by a motor and drive gearbox. They use vanes to spin the liquid inside a cylinder with an inlet valve at one end, creating pressure that can be used as needed

- Clutch Pumps: Clutch pumps are similar to gear or piston pumps in that they use a rotating part-typically impeller, but sometimes a piston-to create hydraulic pressure. The difference is that the clutch pump has no capacity for storing fluid, and it can’t generate any significant flow rates

- Dump Pumps: Dump Pumps are used in applications that require a very small flow rate. Most dump pumps have only one moving part-a piston or an impeller, which is held back with check valves so it can’t move unless there’s enough pressure to overcome the valve

- Refuse Pumps: Refuse pumps are mainly used in wastewater systems. They pump sewage uphill to a higher elevation, and the pumping is done by using valves, which control flow rates

Conclusion

Hydraulic Pumps are being utilized in more and more different industries, which is why it’s important to know the types of hydraulic pumps that exist. This way, you can ensure that your hydraulic pump will be compatible with the needs of your industry.

Hopefully, this article has helped provide some insight into Hydraulic Pumps and how they’re used in different industries for different purposes. It would be best if you never were without one, and they should always be serviced regularly to ensure that you’re getting the best performance possible.

If there are any questions about hydraulic pumps or this article, feel free to comment below!

Comments